If you had told me that I could spend hours mapping processes in my 30s when I was in high school, I would have actually believed you. I was always thinking about how to map steps out. This specifically came to mind as I was a huge skateboarding, gymnastics, and trampolining fan as I used to plan things out. I would break tricks down into its elements to understand how each component contributed to the overall trick. From here, you can think about how tricks can be combined into a routine that has the end desire of being aesthetically pleasing or maximise your points collected.

My second time through university, I signed up for a subject, BISM2203 – Business Process Management. It would only be 2 weeks before I really understood what was in front of me. It was something that I had been missing for years of my life, but extremely thankful that I had found it when I did. Given some processes that I had learned during my Sound Design degree, I hadn’t realised at the time that I had developed some core building blocks that would contribute to my thorough enjoyment of the subject.

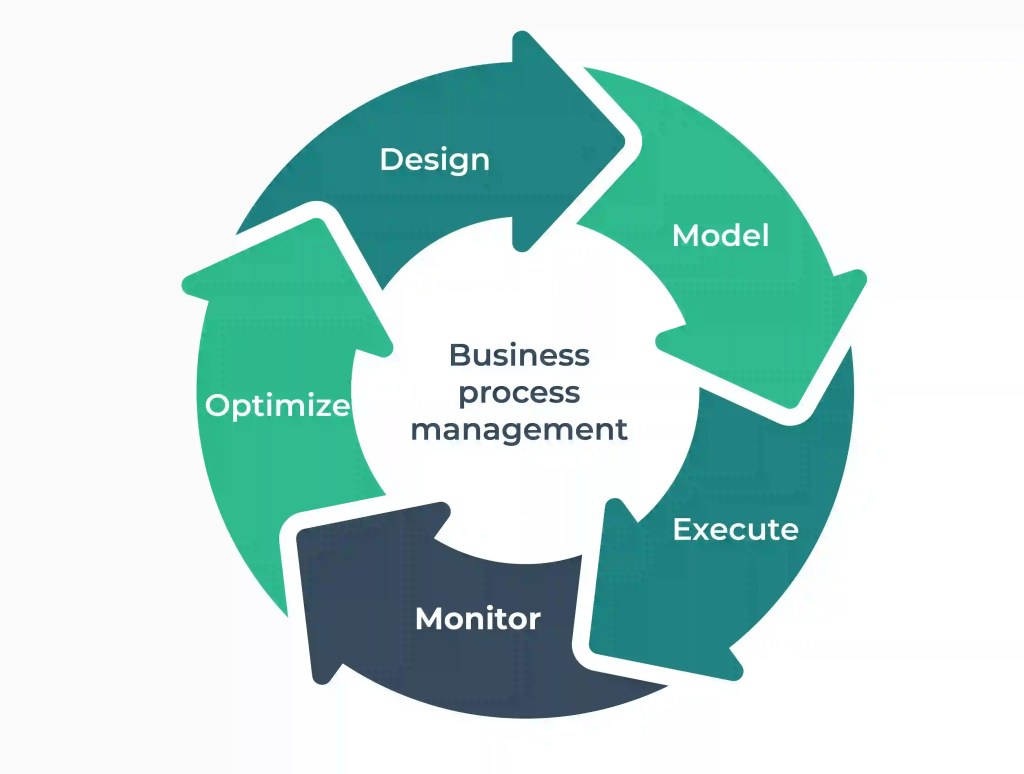

When you utilise Business Process Management (BPM), you enable people to use various methods to discover, model, analyse, measure, improve, optimise, and automate business processes. Essentially, you create a map of tasks that people perform, analyse it, and find the WASTE that creates DOWNTIME (Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra processing). BPM, LEAN, WASTE reduction, and Six Sigma complement each other in improving business efficiency. BPM provides a structured approach to analysing and optimising workflows. LEAN focuses on eliminating waste to enhance value. Six Sigma aims to reduce process variation and defects using data-driven methods. Together, they streamline operations, reduce inefficiencies, and improve quality, resulting in more efficient, effective, and customer-focused processes.

Since I’ve been tasked with completing some BPM mapping at one of my workplaces, I’ve decided to take advantage of this mindset that I’ve been allowed to indulge myself in. This is the first post in a series of 4: Project Outline; As-Is Modelling; WASTE Management; and To-Be Modelling & Analysis. In this first post, I will outline a background of a business case, the processes that are to be mapped, practices that should be implemented, and the value that can be derived from it.

Background & Task

Building Your Future Facilities (BYFF) is a company that develops new industrial buildings and facilities, and has recently been bought by a new company, BYFF’s owner (BYFFO). BYFFO’s CEO has hired you to review how BYFF works with various contractors and consultants in order to reduce risk when developing new and complex projects. BYFFO believes that BYFF has established a best practice approach to the early contractor involvement phase, leading to better outcomes in terms of cost, quality and schedule. This access to best practice processes is one of the reasons that BYFFO acquired BYFF. The new owner is keen to see how BYFF’s early contractor involvement stage operates today. BYFFO intends to deploy the same best practices in its other infrastructure development projects in Australia. It plans to do this by sharing a standards-based process model with the Directors of the other businesses at a level of detail that allows them and their teams to understand the key steps, and quickly integrate them into their projects.

To this end, the owner has ensured that you have had access to key personnel in BYFF, allowing you to review existing written descriptions or models of how things happen at the company, conduct interviews, and observe the process in action. As a result, you have prepared the following process description of BYFF’s early contractor involvement process.

Early Contractor Involvement Process

As soon as the local government confirms receipt of BYFF’s Development Approval (DA) application, BYFF’s Contracts & Procurement (C&P) Manager finalises a document called Invitation To Tender (ITT) and issues it to 3 construction companies. This document asks them to provide a proposed response to the ITT, including their cost proposal, to work alongside BYFF and its other suppliers to finalise plans for the construction phase. The construction companies have 4 weeks to respond to the ITT in full.

Since BYFF C&P wants to ensure it gets competitive bids, it requires those who intend to respond in full to confirm their interest within 1 week of receiving the ITT. If a company fails to respond within 1 week, BYFF’s C&P Manager sends a reminder to that company, giving them 3 days to confirm their interest. If after 3 days, BYFF has not received a response, the C&P Manager will send the ITT to a 4th interested company, and inform all companies that the date is now 4 weeks from that new date (thus ensuring that the 4th contractor has time to prepare a good response). BYFF does not seek further confirmation from the 4th company that it will respond. All contractor responses must be received by the Tenders emails inbox BYFF by 3pm on that date.

If a consultant requests an extension beyond the 4 weeks, BYFF’s C&P Manager will consider it, and may grant an additional 2 weeks, depending on the circumstances. If the extension is granted, the C&P Manager will inform all contractors of the revised submission date for their responses, and if not, she will inform the requesting contractor that the request has been rejected. In the great majority of cases, the contractors do not request an extension, as they are concerned it may undermine BYFF’s impression of their ability to deliver on time in the construction phase.

At 3.01pm on the day submissions are due, BYFF’s C&P Manager opens the Tender Inbox, and prints each submission in triplicate: one for each of the 3 members of the Contracts Assessment Panel which will meet within 3 days to jointly review and assess the responses. This Assessment Panel will start by conducting a Health, Safety & Environmental (HSE) assessment to ensure the contractors have a good record in these areas, followed by a Technical Assessment to confirm that the contractors have proposed the right technical experts, and propose a satisfactory schedule. Concurrently, the C&P Manager reviews the cost component of each company’s response, and summarises them in a standardised format which is then provided to the Contract Assessment Panel. Once costs are received, the Assessment Panel reviews those contract documents including cost, HSE and Technical assessments, and makes a decision to select the preferred contractor. The Panel then informs the C&P Manager, who then prepares, sends the selected contractor a letter and includes a contract to be signed. The contractor must sign and return this contract (including any updates to it) within 5 days, during which time various terms can be negotiated as needed. If the contractor does not contact BYFF’s C&P Manager to return the signed contract or to negotiate the terms within 3 days, the C&P Manager will contact them on day 4 to remind them they must sign and return the contract by day 5. So far, this approach has always delivered a successful outcome for BYFF.

Now that the contractor has been selected, BYFF’s PM arranges a Team Kick-off meeting between the selected Construction contractor, the external Consultant engineer, and him. The output of this meeting is a confirmed scope for the construction contractor and consultant engineers to work on, and an agreed schedule of team meetings for the remainder of the EOI process. Over the next few months, this process is consistent: on the 25th day of each month, the PM will request project updates from both external suppliers to be delivered by the 29th of each month. By the 29th of each month, the PM receives two documents by email from each of the suppliers, comprising a written report on progress and an invoice. Once he has received both, the PM reviews the reports, and if necessary, seeks clarifications from the relevant supplier prior to the workshop the following day. At the same time, he also reviews the invoices, and if satisfied, approves and emails a scan of the invoices to the C&P Manager to process it. If the invoice was different to the PM’s expectations, he contacts the supplier, seeking clarification and a new invoice (if required). Sometimes the invoice is accepted without further change as a result of that clarification.

The C&P Manager will enter the invoice in the procurement module of the ERP system, which will automatically process the invoice in the ERP and instruct the bank to pay it. The PM also chairs a team workshop on the 15th and 30th of each month where the team reviews its collective progress. These workshops are designed to allow the PM to review progress, highlight challenges and identify solutions rapidly, which, over the 4 months, will provide BYFF with a reliable plan, cost and schedule for constructing its new facilities. Once the PM assesses these outputs are complete, the ECI phase is successfully completed.

After the ECI process is complete, the PM requests that the contractors send their final invoices. These will be reviewed and, if appropriate, approved by the PM, following the invoice review and payment process outlined above.

At any stage after arranging the ECI kick-off meeting, the local government may provide BYFF’s PM with its development approval for the project, in which case the process continues. If the local government rejects the development application, this means there is no point in continuing the ECI, so results in BYFF’s PM informing the contractors that BYFF is stopping the ECI process abruptly. The possibility has been contemplated in the contract, so the external contractors will issue a final invoice once that notice has been given, which is reviewed in the usual Accounts payable process, and the project will end.

Implemented Practices

There are 10 principles that guide the practices of Good BPM:

- Context Awareness: BPM should fit the organisational context. It should not follow a cookbook approach.

- Continuity: BPM should be a permanent practice. It should not be a one-off project.

- Enablement: BPM should develop capabilities. It should not be limited to firefighting.

- Holism: BPM should be inclusive in scope. It should not have an isolated focus.

- Institutionalisation: BPM should be embedded in the organisational structure. It should not be an ad hoc responsibility.

- Involvement: BPM should integrate all stakeholder groups. It should not neglect employee participation.

- Joint Understanding: BPM should create shared meaning. It should not be the language of experts.

The last three principles outline what should be achieved by using BPM:

- Purpose: BPM should contribute to strategic value creation. It should not be done for the sake of doing it.

- Simplicity: BPM should be economical. It should not be over-engineered.

- Technology Appropriation: BPM should make opportune use of technology. It should not consider technology management as an afterthought.

BPM is crucial for optimising organisational workflows and ensuring that business operations are efficient, effective, and adaptable. Integral to this are practices such as process modelling, process identification, process architectures, process discovery, qualitative analysis (Lean vs. Six Sigma), quantitative analysis, process improvements, and process implementation and monitoring. These practices form the backbone of effective BPM and align with ten guiding principles to maximise business value and process efficiency.

Process modelling is vital as it provides a visual representation of business processes, enabling stakeholders to understand and analyse workflows effectively. This practice helps identify inefficiencies, redundancies, and bottlenecks, facilitating communication and ensuring everyone has a clear understanding of processes. It aligns with the principles of context awareness and joint understanding, as it tailors models to organisational contexts and fosters shared meaning among stakeholders.

Process identification and process architectures are foundational, involving the recognition and definition of various processes within an organisation and understanding their interconnections. This comprehensive mapping prioritises processes for improvement based on their impact on business objectives and their role within the broader process architecture. These practices align with holism and institutionalisation, ensuring that efforts are inclusive in scope and embedded within the organisational structure.

Process discovery gathers detailed information about existing processes through workshops, interviews, and direct observation. This practice is vital for BPM as it provides a factual basis for process models and identifies the actual workflow versus the perceived one. Accurate process discovery uncovers root causes of inefficiencies and ensures improvements are based on a true understanding of current operations, adhering to the principle of involvement by integrating stakeholder insights.

Qualitative analysis, through Lean and Six Sigma, is essential for BPM. Lean focuses on waste reduction and value creation, while Six Sigma aims at reducing variability and improving quality through statistical methods. Integrating these approaches in BPM enhances process efficiency and effectiveness comprehensively. Lean helps in streamlining processes and eliminating non-value-adding activities, while Six Sigma provides tools to address defects and ensure consistency. This dual approach supports the principles of enablement and continuity, ensuring BPM develops capabilities and remains a permanent practice.

Quantitative analysis and process improvements are crucial for providing data-driven insights into process performance. By measuring key performance indicators (KPIs) and analysing process data, organisations can identify trends, benchmark performance, and set realistic improvement targets. Quantitative analysis supports informed decision-making and helps validate the impact of process improvements, ensuring changes lead to measurable benefits. This practice aligns with the principle of simplicity, ensuring BPM is economical and not over-engineered.

Process implementation and monitoring are the final steps in the BPM cycle. Effective implementation ensures improvements are applied correctly and processes are executed as designed. Continuous monitoring tracks performance, identifies deviations, and allows for necessary adjustments. This ongoing oversight ensures processes remain aligned with business goals and continue delivering desired outcomes. This practice reflects the principles of purpose and technology appropriation, as BPM contributes to strategic value creation and makes opportune use of technology.

Derived Value

Adhering to good BPM principles and practices creates significant value for organisations. Enhanced operational efficiency is a primary benefit. By systematically identifying and eliminating inefficiencies through process modelling, discovery, and Lean analysis, organisations can streamline workflows and reduce waste. This leads to faster turnaround times, lower operational costs, and improved resource utilisation. Robust BPM practices ensure processes are optimised and aligned with strategic goals, leading to more effective execution of business strategies and a stronger competitive position.

Improved quality and customer satisfaction are substantial outcomes of good BPM principles. Qualitative analysis, particularly through Six Sigma methodologies and quantitative analysis, helps in reducing process variability and defects, resulting in more consistent and reliable outcomes. Higher quality translates to greater customer satisfaction and loyalty, as customers receive more dependable and superior offerings. Continuous process monitoring and improvement ensure the organisation can adapt to changing customer needs and market conditions, maintaining high standards and customer trust over time.

In conclusion, integrating BPM principles with practices like process modelling, identification, discovery, qualitative and quantitative analysis, and implementation and monitoring ensures comprehensive and effective process management. This integration drives sustained business value, operational efficiency, cost savings, and customer satisfaction, positioning organisations for long-term success and competitiveness.

How would you map this process? Give it a go then check in for the 2 of 4 posts in the series.

4 responses to “73 – Business Process Management Series: 1 Project Outline”

[…] is the last instalment of the Business Process Management Series. The first in the series was an introduction to Business Process Management (BPM), outlining its principles, practices, and […]

[…] Business Process Management Series […]

[…] into the fun stuff — well, what I consider the fun stuff. This is where we take all of that initial hard work to understand the business’ needs, values, key stakeholders, operations, and how they are all […]

[…] is all about, right? Reviewing and updating previous notions or ideas; see more in the continuing BPM series over the next few weeks. After reviewing this code, I’ve made the following updates to it, […]